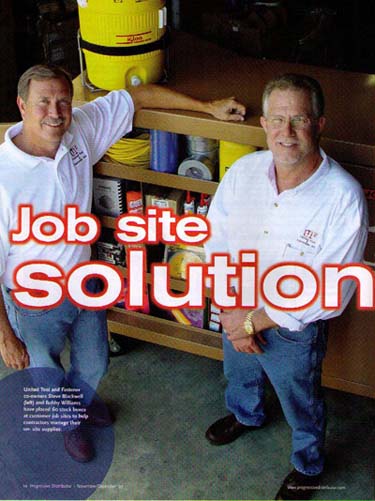

Breakthrough solutions often come as a result of careful market research and planning. Sometimes, however, the best ideas occur on the spur of the moment. For example, Bobby Williams and Steve Blackwell, co-owners of United Tool and Fastener in Houston, had been discussing ways to provide faster service to major customers. They were looking for a way to keep contractors supplied with the products they need on the job site in a more timely manner.

Breakthrough solutions often come as a result of careful market research and planning. Sometimes, however, the best ideas occur on the spur of the moment. For example, Bobby Williams and Steve Blackwell, co-owners of United Tool and Fastener in Houston, had been discussing ways to provide faster service to major customers. They were looking for a way to keep contractors supplied with the products they need on the job site in a more timely manner.

They intuitively knew that if they could provide faster service to customers, it would help solidify their business relationships and lock out big box stores and other competitors that compete primarily on price. But they hadn't come up with the precise plan for making that happen. Then one day Williams was taking a coffee break with a contractor at a construction site for a 28-story downtown office building. "You've got to come up with a solution for me", the job superintendent told Williams. The two sat there and watched as a plumber, who earns $25 an hour, ride the construction elevator down to the street level, walked across the street to pick up a box of 3/8-inch hex nuts, waited for the elevator to return to the street level, then returned to finish the job he was working on. "It took more than an hour of that plumber's time to pick up about $2 worth of supplies, " Williams says.

That's when Williams came up with his breakthrough idea. United Tool could put storage boxes on the job site for stocking common materials such as nuts, bolts, fasteners, couplings and other supplies. United Tool pays for the storage boxes, which cost about $1,000 each, and as many keys as the customer desires, and requires two stipulations in return. The boxes can't be used to store power tools (to reduce incidents of theft), and the customer can't use the boxes to hold any supplies purchased from competitors.

In the first year after introducing the program, United Tool installed 25 stock boxes on job sites. Today, it has 60 boxes at customer sites. Some boxes have been in service for more than four years.

"The customer keeps moving them from job to job," says Sales Manager John Calhoun.

Some construction sites have multiple stock boxes, with each one designated for use by different trades. United Tool salespeople check the boxes on a weekly basis - more often if necessary - to keep them stocked with appropriate supplies. The distributor invoices customers for inventory stored in each box. If products aren't used, the customer receives a credit.

"Our salesmen get together with the job superintendent to find out what's needed on the job," Calhoun says. "Our guys closely monitor what's going in and out of the box. If they see something that hasn't moved in a while, it behooves them to take it out so we don't have to issue a big credit."

Placing material closer to the job site helps contractors because supplies are more accessible to work crews. The solution also benefits United Tool because it keeps competitors from making inroads with major customers.

"When one of our competitors calls on a customer where we have boxes, the superintendent can say, 'We have a deal with United Tool.' The conversation's over," says Blackwell.

United Tool calls the program its job-site stocking partnership. The company hires a professional to label each box with a United Tool logo and the customer's logo, so the box doubles as a storage center and a billboard on the job site.

Long-term Relationship

The job-site stocking partnership is one reason why this $20 million distributor has experienced steady growth in the competitive markets of Houston, San Antonio, and College Station, TX. The company hopes to expand into additional markets as opportunities arise.

"We've been in this market a long time, so we have long-term relationships with a lot of people. There's a lot of loyalty between us and our customer base," says Blackwell.

Blackwell says customers are loyal because United Tool offers better customer service and value than the competition, even though that doesn't necessarily mean the lowest price.

"If people like our service, they'll be willing to pay a higher price. Plus, we have the product on the shelf. The competition might quote a lower price, but they might not have it. We're small enough that we can tweak our inventory for customers," he says.

The company handles more than 6,000 line items and maintains nearly $4 million in inventory across three locations.

Easy access means fast service

Having a knowledgeable, trained workforce is a value-added benefit that's difficult to measure. Seven of the company's 12 outside salespeople have earned the Certified Tool Specialist designation from the Evergreen Marketing Group, and Calhoun has achieved Diamond-level status. To earn certification, salespeople must complete more than 137 hours of continuing education covering product, applications and selling skills. To achieve Diamond-level status, the sales professional must complete 52.5 additional hours of professional development and have teaching experience. Only nine distributors’ salespeople in the country have earned the Diamond level designation to date.

"Our guys are all commissioned salespeople," says Blackwell. "The more they sell, the more they make. The more product knowledge they have, the more they sell."

United Tool also received the 2006 Distributor Member of the Year Award from Evergreen, recognizing the company's support of Evergreen suppliers and participation in Evergreen programs.

The blitz is on

In addition to sending salespeople to virtually every training session that Evergreen offers, United Tool also typically schedules product training or sales blitzes with preferred suppliers at least quarterly. The company believes it's important for salespeople to work closely with suppliers reps to bring new products and expertise to customers. A recent sales blitz introduced customers to new power tool accessories introduced by DeWalt, United Tool's primary power tool line. "Our guys can learn a lot on joint calls with the rep because they're experts in the products," says Williams. "Hopefully, our salespeople can absorb enough information that they can pass it along to their customers later on."

Conducting promotional efforts and joint sales calls with vendors is one way to build relationships with key suppliers. Williams says it's important for vendors to know that salespeople are actively promoting their brand.

"There's no reason to have 10 3/8-inch drills on the shelf that drill the same hole." Williams said. "Because United Tool has always carried only one major brand in each product category, those suppliers give them all the support they need.”

"We're partners with our vendors," he says. "We don't play vendor against vendor. DeWalt is our major tool line. We may have one or two SKU's of another brand, but we don't want to duplicate our inventory."